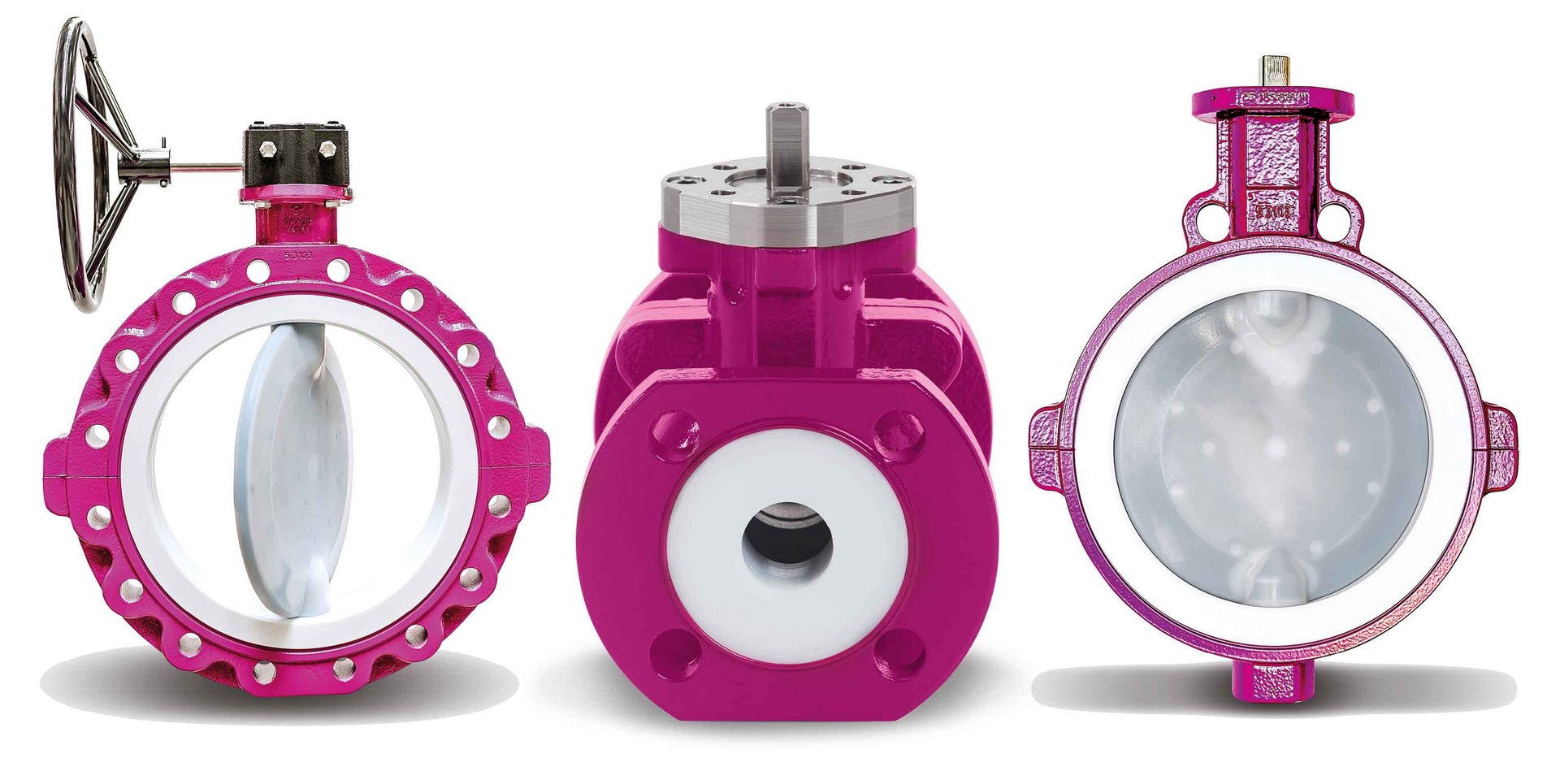

ChemValve - Premium PTFE Lined Valves direct from the manufacturer

ChemValve-Schmid, a private and independent company, is a leading European PTFE valve manufacturer, with three decades of experience in valve development and innovation.

This is reflected in the finely crafted details: ChemValve's customary, sophisticated sealing systems and precision engineering, alongside the in-house developed production machines.

Every single PTFE valve - the ChemFlyer | CST PTFE Lined Butterfly Valve, the ChemBall | CSB PFA Lined Ball Valve and the ChemDisc | DTEF & ChemSwing | CSC - is built and tested according to international standards, guaranteeing cycle rates and service life in applications with corrosive media.

Through consistently "insourcing instead of outsourcing", dependencies on third parties are minimised and quality, safety & delivery are guaranteed.

Why is PTFE used in industrial valves?

PTFE has many outstanding properties which make it suitable for use in industrial valves. It is an inert compound, meaning that is extremely unreactive and stable when it comes into contact with a large range of aggressive or corrosive substances, such as chlorine and hydrogen fluoride. This also means it is well suited for use in food manufacturing.

PTFE is able to operate in a wide temperature range, from -270°C to +260°C and is additionally very resistant to most chemicals and environmental factors such as a UV-rays and ozone.

For industrial applications with aggressive media or with demanding anti-friction requirements, PTFE is the most widely used fluroplastic worldwide.

What is PTFE? - From accident to universal material

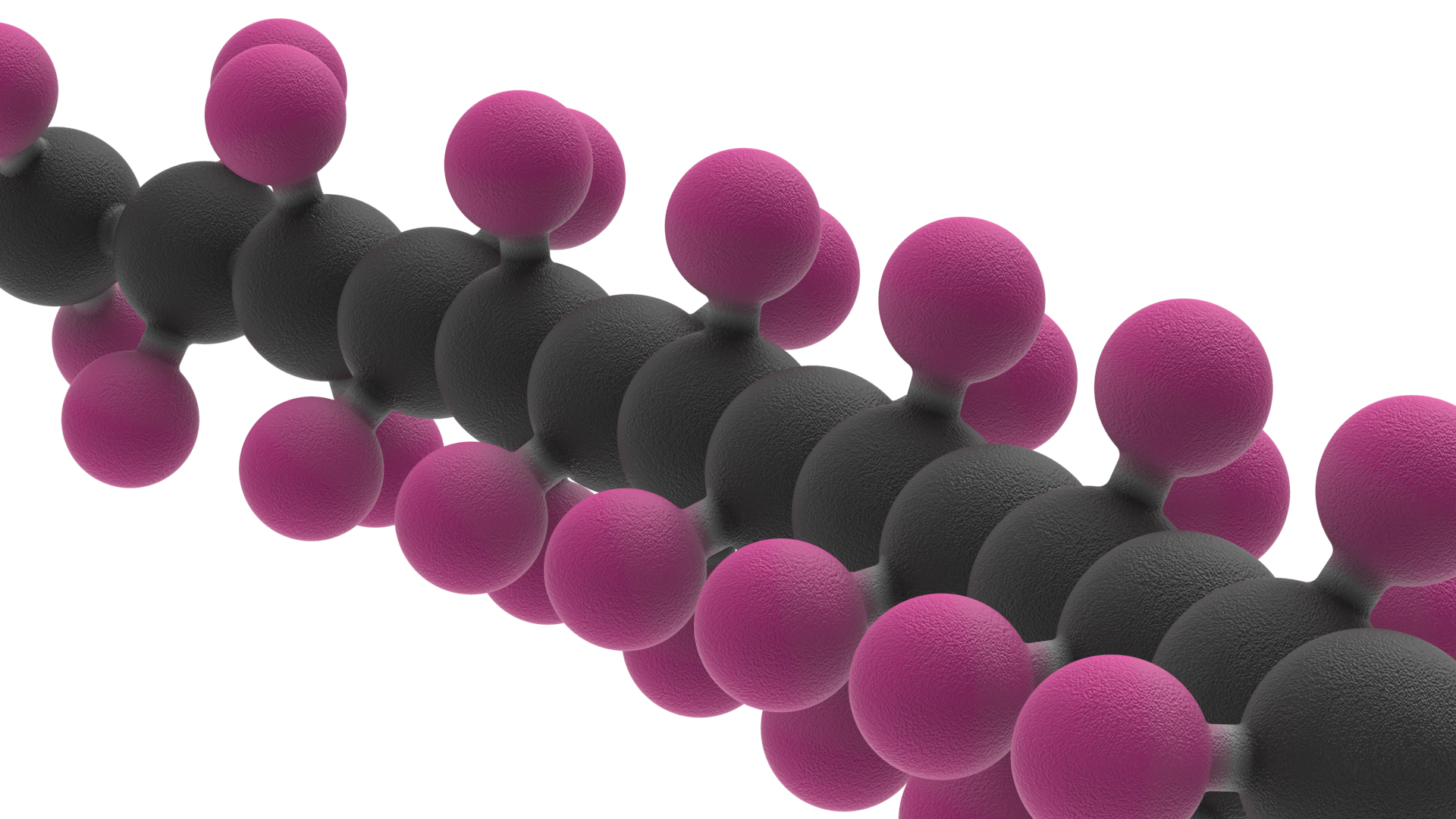

PTFE (Polytetrafluoroethylene) is a high-performance polymer, which was discovered by accident about 100 years ago during attempts to create a new refrigerant. From these humble beginnings, PTFE is now used in many everyday items, from non-stick pans to waterproof clothing.

PTFE belongs to the fluoropolymers and is classified as a thermoplastic due to its one-dimensional, chain-formed carbon and fluorine molecule.

By adding Perfluoropropylvinyl Ether (PPVE) during the polymerisation process, modified PTFE and PFA (perfluoroalkoxy alkane) can be produced, providing a greater range of durability & permeation resistance compared to virgin PTFE.

Contact

ChemValve-Schmid AG

Dünnernstrasse 540

4716 Welschenrohr

Schweiz

Tel: +41 32 639 50 10

sales@chemvalve-schmid.com